The materials used to construct our homes and workplaces are meant to provide safety and shelter. However, some widely used building materials have come under scrutiny for their potential to cause long-term health issues. Awareness of these materials is growing as research uncovers the links between chronic exposure and various illnesses. For homeowners, builders, and occupants alike, understanding these risks is the first step towards creating healthier indoor environments.

1. Asbestos

Asbestos, a group of naturally occurring mineral fibers, was widely used in construction materials for its heat resistance and insulation properties until the late 1970s, according to the Placer County Air Pollution Control District. Common applications included insulation, flooring tiles, roofing, and some cements. The danger arises when asbestos-containing materials are disturbed or deteriorate, releasing microscopic fibers into the air. Inhalation of these fibers can lead to serious lung diseases, including asbestosis, lung cancer, and mesothelioma, a rare and aggressive cancer.

The long latency period between exposure and the onset of these diseases makes it particularly insidious. Many individuals who were exposed decades ago are only now being diagnosed. Because asbestos was so prevalent in older buildings, renovations and demolitions require careful handling and disposal procedures to prevent fiber release and protect workers and the public. Even intact asbestos-containing materials can pose a risk if they are damaged or disturbed.

2. Lead-Based Paint

Lead was a common ingredient in paint until it was banned for residential use in the United States in 1978, the Centers for Disease Control and Prevention (CDC) notes. Homes built before this time are highly likely to contain lead-based paint, often under layers of newer paint. Deteriorating lead paint can create lead dust and chips, which are particularly hazardous to young children. Exposure to lead can cause developmental problems, learning disabilities, and damage to the brain and nervous system.

Even seemingly intact lead paint can become a hazard during renovations or repairs that involve sanding or scraping. Lead dust can settle on surfaces and be ingested or inhaled, posing a significant risk. Safe lead paint removal and lead-safe renovation practices are crucial in older homes to protect occupants, especially children and pregnant women, who are most vulnerable to lead’s harmful effects.

3. Formaldehyde

Formaldehyde is a colorless gas with a strong odor and is used in the production of many building materials, particularly adhesives and bonding agents in pressed wood products like plywood, particleboard, and paneling, according to the Minnesota Department of Health. It is also found in some insulation materials and finishes. Formaldehyde is a known respiratory irritant and a probable human carcinogen. Exposure can cause eye, nose, and throat irritation, coughing, headaches, and nausea. Long-term exposure has been linked to an increased risk of certain cancers.

The off-gassing of formaldehyde from these materials can contribute to poor indoor air quality, especially in new buildings or homes with recent renovations. Choosing low-VOC (volatile organic compound) or formaldehyde-free building materials can significantly reduce exposure.

4. Volatile Organic Compounds (VOCs)

VOCs are a broad category of chemicals that vaporize at room temperature and are emitted from a wide range of building materials, including paints, varnishes, adhesives, sealants, flooring, and insulation, according to the Construction Marketing Association. Many VOCs are known to have adverse health effects, ranging from short-term symptoms like headaches, dizziness, and eye and throat irritation to long-term effects such as respiratory issues, nervous system damage, and cancer. Indoor levels of many common organic pollutants are significantly higher than outdoor levels.

The off-gassing of VOCs is typically highest in new materials and gradually decreases over time. Choosing building materials with low or zero VOC content is essential for creating healthier indoor environments. Proper ventilation during and after construction or renovation can also help to reduce VOC levels.

5. Phthalates

Phthalates are chemical compounds used to soften plastics and are found in various building materials like vinyl flooring, wall coverings, and some adhesives. Several studies suggest that exposure to certain phthalates can have endocrine-disrupting effects, potentially interfering with hormone systems and leading to developmental and reproductive issues, although research is ongoing. The National Institutes of Health (NIH) has conducted studies on the potential health effects of phthalate exposure.

While some phthalates have been restricted in children’s products, they can still be present in building materials. Choosing alternative materials and ensuring good ventilation can help reduce potential exposure. Consumers are increasingly looking for phthalate-free options in various products, and this awareness is extending to building materials as well.

6. Flame Retardants

Certain flame retardant chemicals, historically added to insulation, furniture foam, and textiles used in buildings, have raised health concerns. Some of these chemicals, such as polybrominated diphenyl ethers (PBDEs), have been linked to neurodevelopmental issues, endocrine disruption, and cancer in animal studies, with human exposure being a concern. The EPA has taken action to restrict or ban some of these substances.

While flame retardants are intended to improve safety, the potential health risks of certain types have led to a shift towards safer alternatives. When selecting insulation and other materials, it’s important to inquire about the types of flame retardants used and opt for those with a better safety profile. Building codes are also evolving to address the use of potentially harmful flame retardants.

7. Silica Dust

Silica is a naturally occurring mineral found in many construction materials like concrete, brick, mortar, and drywall. When these materials are cut, ground, or drilled, they can release fine crystalline silica dust into the air. Inhaling this dust can lead to silicosis, a serious and incurable lung disease.

Workers in construction and demolition are at the highest risk of silica exposure. OSHA has implemented stricter regulations to protect workers from respirable crystalline silica dust. Proper ventilation, respiratory protection, and dust control measures are crucial on construction sites to prevent long-term lung damage.

8. Wood Dust

Working with wood, especially during cutting, sanding, and drilling, generates wood dust. While often considered a natural material, prolonged and high-level exposure to wood dust, particularly from hardwoods, is classified as a known human carcinogen with links to nasal and sinus cancers.

Proper ventilation and the use of dust collection systems and respiratory protection are essential in woodworking and construction to minimize inhalation of wood dust. Different types of wood dust may also have varying levels of toxicity and allergenic potential.

9. Radon

Radon is a naturally occurring radioactive gas that can seep into buildings from the ground. It is invisible, odorless, and tasteless, making it undetectable without testing. Long-term exposure to high levels of radon is the second leading cause of lung cancer after smoking.

Radon levels can vary significantly depending on the local geology and building construction. Radon testing is recommended for all homes, and mitigation systems can be installed to reduce levels if they are found to be high. Building codes in some areas now require radon-resistant construction techniques.

10. Chromated Copper Arsenate (CCA) Treated Wood

CCA was a common wood preservative used to protect lumber from rot and insect infestation, particularly in outdoor applications like decks and playground equipment. However, CCA contains arsenic, chromium, and copper, all of which are toxic. Leaching of arsenic from CCA-treated wood into the soil and potential skin contact were identified as health risks, especially for children.

Due to these concerns, CCA has been largely phased out for residential use, although it may still be found in older structures. When dealing with CCA-treated wood, precautions should be taken to avoid skin contact and inhalation of sawdust, and it should not be burned. Safer alternative wood preservatives are now widely available.

11. Polychlorinated Biphenyls (PCBs)

PCBs are a group of synthetic organic chemicals that were used in various industrial and building materials, including caulking, sealants, and electrical equipment like transformers and capacitors, particularly in buildings built before the 1979 ban. PCBs are persistent environmental pollutants and are classified as probable human carcinogens, with links to a range of other health effects, including immune, reproductive, and neurological problems.

PCBs can leach from old building materials into the air and dust, leading to exposure. Identifying and safely removing PCB-containing materials during renovations or demolitions is crucial. Regulations govern the handling and disposal of PCBs to minimize environmental and health risks.

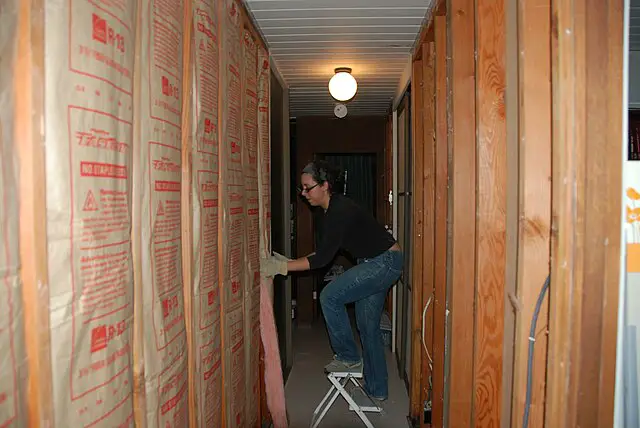

12. Certain Insulation Materials

While insulation is essential for energy efficiency, some types have raised health concerns. Older fiberglass insulation can release fibers that can irritate the skin, eyes, and respiratory system during installation or disturbance. Spray foam insulation, if not properly installed and cured, can release isocyanates, which are respiratory irritants and sensitizers.

Choosing safer insulation alternatives, ensuring proper installation with adequate ventilation and protective gear, and selecting products with low emissions are important considerations. The long-term health impacts of newer insulation materials are continuously being studied.

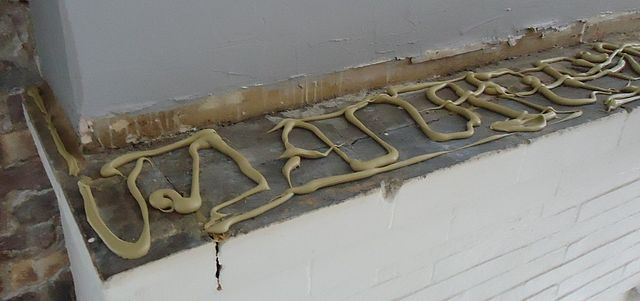

13. Some Adhesives and Sealants

Many construction adhesives and sealants contain VOCs, as mentioned earlier, but some also contain other hazardous chemicals like methylene chloride or toluene. Exposure to these chemicals can cause neurological problems, respiratory issues, and other health effects.

Opting for low-VOC or VOC-free adhesives and sealants is advisable. Ensuring good ventilation during application and allowing adequate curing time can help reduce exposure to harmful fumes. Always check product safety data sheets for specific hazards and precautions.