1. Asphalt Shingles (Basic Grades)

Budget asphalt shingles are slowly disappearing from new construction, even though they’ve long dominated suburban roofs. The problem is that basic three-tab shingles often fail in high winds and have short lifespans. Insurance companies and developers are turning to architectural shingles or metal roofing for longevity and curb appeal. Many cities in storm-prone regions now require materials rated for extreme weather.

While asphalt remains common, the cheap stuff is on its way out. Builders don’t want the reputation of “starter home” quality materials. More durable roofing also reduces warranty claims and maintenance headaches. What used to be standard is now a red flag for quality-conscious buyers.

2. Vinyl Siding

Once the go-to for affordable home exteriors, vinyl siding has quietly fallen out of favor in many new developments. Builders and HOAs are pushing back because vinyl can warp, fade, and crack under heat or impact. It’s also seen as cheap-looking compared to fiber cement or brick, which can drag down neighborhood aesthetics. Fire safety concerns and limited recyclability have sealed its fate in many zoning codes.

Developers now prefer materials like composite cladding that mimic wood but perform better. These options resist weather damage and meet stricter energy codes. Vinyl’s biggest advantage—its low price—just isn’t enough to outweigh its durability issues anymore. In upscale or eco-focused communities, vinyl simply doesn’t make the cut.

3. Laminate Countertops

Laminate counters were once a DIY dream, but they’ve been replaced by more durable, natural-looking surfaces. In new builds, quartz, granite, and even solid-surface acrylics have become the baseline. Laminate just can’t stand up to heat or scratches the way these materials can. Plus, real estate agents say laminate can instantly date a kitchen.

Developers also find that buyers associate laminate with cheap apartment finishes. It’s one of those materials that signals “budget build” at first glance. With engineered quartz prices dropping, there’s less financial incentive to go cheap. Laminate might still show up in rental properties—but rarely in new homes for sale.

4. Hollow-Core Interior Doors

These lightweight, inexpensive doors are being swapped out for solid-core models in many modern builds. Hollow-core doors are notorious for feeling flimsy and transmitting every sound. They’re also easily damaged and don’t hold hardware well, which creates maintenance headaches for property managers. Soundproofing standards and buyer expectations have simply moved past them.

Solid-core or composite doors offer better noise control, weight, and a more substantial feel. Developers know that tactile quality matters when you close a door—it’s a subtle signal of craftsmanship. Even mid-range homes now feature heavier doors to enhance privacy. Hollow-core designs are mostly relegated to budget remodels or garages.

5. Popcorn Ceilings

Popcorn or “acoustic” ceilings were once installed to hide imperfections and muffle noise cheaply. But they’re banned in many new developments because they can contain asbestos (in older materials) and are notoriously hard to clean. Even asbestos-free versions still collect dust and shadows, making interiors look dated. Most buyers now see them as a renovation project waiting to happen.

Smooth or lightly textured finishes are the new norm, paired with modern lighting designs. Builders also avoid popcorn because it complicates ceiling repairs and paint touch-ups. Flat ceilings simply photograph better in listings—something developers are very aware of. The popcorn look is now reserved for history books and home-flipping horror stories.

6. MDF Trim and Molding

Medium-density fiberboard used to be the budget-friendly alternative to real wood trim. But in new developments, it’s being replaced with PVC or solid pine due to moisture issues. MDF swells, warps, and even disintegrates when exposed to humidity, especially in bathrooms or basements. Homeowners discovered this the hard way after just a few years of use.

PVC trim, by contrast, resists mold and doesn’t need repainting as often. Developers appreciate its long-term performance and low maintenance costs. The small cost savings of MDF just don’t justify its short lifespan. It’s another example of “cheap now, expensive later” materials being phased out.

7. Carpet in Living Areas

Wall-to-wall carpet once symbolized cozy comfort, but it’s being edged out by hard-surface flooring in most new homes. Developers prefer luxury vinyl plank or engineered wood, which are easier to clean and last longer. Carpet traps allergens, stains easily, and wears unevenly in high-traffic areas. Buyers also see it as less hygienic, especially post-pandemic.

You’ll still see carpet in bedrooms or basements, but rarely in main living spaces. Hard flooring simply photographs better and boosts resale appeal. Builders know that offering carpet can make a home feel dated before it’s even occupied. The move toward cleaner lines and lower maintenance has made carpet a casualty of modern design.

8. Cheap Vinyl Windows

Single-pane or low-grade vinyl windows are vanishing from new developments. These older designs fail to meet modern energy efficiency standards and often leak air. Double- or triple-pane windows with advanced coatings are now standard in most jurisdictions. Builders who use outdated windows risk failing inspection or losing buyers to energy-conscious competitors.

Today’s homebuyers expect Energy Star certification and lower utility bills. The upfront cost of better windows pays off in marketing appeal and sustainability credits. Cheap vinyl windows simply can’t compete with improved composites and aluminum-clad options. The message is clear: energy waste is out, and performance glass is in.

9. Particleboard Cabinet Boxes

Particleboard cabinetry is being replaced by plywood or MDF cores with better durability. While it’s inexpensive, particleboard crumbles when wet and can’t handle heavy loads. Builders learned that cheap cabinets lead to callbacks, complaints, and poor reviews. Especially in kitchens and bathrooms, water resistance has become a deal-breaker.

Plywood boxes resist warping and are easier to refinish or repair. Developers now market cabinetry quality as part of their premium upgrades. Particleboard might still show up in rental units, but it’s largely banned in owner-occupied developments. Homebuyers can literally feel the difference in sturdiness when they open a door or drawer.

10. Non-Low-VOC Paints

Paint formulations have changed drastically in recent years due to indoor air quality concerns. Many developments now prohibit high-VOC (volatile organic compound) paints that release harmful fumes. These compounds contribute to poor air quality and can cause headaches or respiratory irritation. Building codes and green certifications increasingly require low- or zero-VOC alternatives.

Modern low-VOC paints perform just as well and come in every sheen and color imaginable. Builders prefer them because they make it easier to market homes as “healthy living” environments. VOC limits are also part of many state energy programs and LEED standards. High-VOC paints aren’t just old-fashioned—they’re noncompliant.

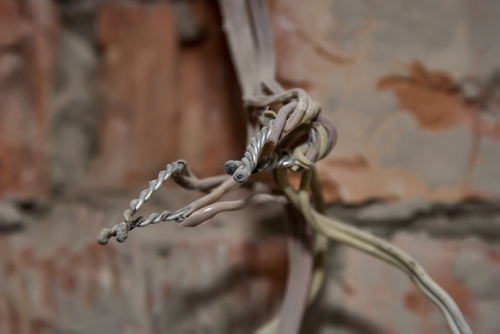

11. Aluminum Wiring

Aluminum wiring, popular in the 1960s and 1970s, is strictly prohibited in modern residential construction. It’s a known fire hazard due to its tendency to oxidize and loosen at connections. Most codes now require copper or copper-clad aluminum wiring for safety. Builders caught using aluminum face hefty penalties and inspection failures.

Copper is more expensive, but it’s far more stable and conducts electricity more efficiently. Developers can’t afford the liability risk of outdated materials in brand-new homes. Insurance companies also refuse coverage for homes with aluminum circuits. It’s one of those “once bitten, forever banned” materials in the industry.

12. Pressed Wood Subflooring

Pressed or particle-based subflooring was once a cheap solution for budget builds. But it’s fallen out of use because it swells and deteriorates when exposed to even small amounts of moisture. Developers have switched to oriented strand board (OSB) or plywood, which perform far better under stress. Pressed wood simply can’t meet modern load-bearing or moisture-resistance standards.

Flooring failures are costly and bad for reputation—two things developers avoid at all costs. OSB panels are engineered to stay flat and handle heavy flooring systems. While the upgrade costs more, it reduces warranty claims and callbacks. Pressed wood now serves as a cautionary tale in builder training manuals.

This post 12 “Budget” Materials That Are Quietly Banned in New Developments was first published on Greenhouse Black.