1. Urea-Formaldehyde Foam Insulation (UFFI)

UFFI sounds appealing because it promised airtight insulation in older homes. Builders stopped using it when occupants complained of strong odors and respiratory irritation. The foam releases formaldehyde gas, especially when improperly installed. Health concerns quickly overshadowed its insulation benefits.

From a building science standpoint, it also shrank and cracked over time. That meant air leaks and reduced performance. Modern spray foams and dense-pack cellulose solve the same problems without toxic off-gassing. UFFI now belongs firmly in the “experiment gone wrong” category.

2. Asbestos Insulation

Buyers still ask about asbestos because they remember it as a miracle fireproofing material. Builders stopped using it once the health risks became undeniable, especially its link to lung cancer and mesothelioma. By the late 1970s, most residential uses were banned or heavily restricted. Today, it’s only encountered during renovations of older homes, not in new construction.

From a builder’s standpoint, asbestos is a liability nightmare. Disturbing it requires licensed abatement, specialized containment, and strict disposal rules. That adds cost, risk, and delays that simply aren’t worth it. Modern mineral wool and fiberglass do the job safely without the baggage.

3. Polybutylene Plumbing Pipe

Polybutylene is one of those materials buyers vaguely remember hearing “something went wrong” about. Builders abandoned it because it reacts poorly with chlorine in municipal water supplies. Over time, the pipes become brittle and fail without warning. Massive class-action lawsuits in the 1990s sealed its fate.

From a construction perspective, unpredictability is unacceptable. A pipe that looks fine but bursts internally is a builder’s worst nightmare. Copper, PEX, and CPVC all proved far more reliable. Today, polybutylene is a red flag during inspections, not a viable option.

4. Knob-and-Tube Wiring

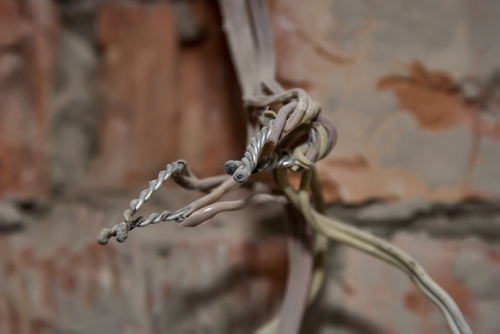

Knob-and-tube wiring gets asked about because it’s still present in many pre-1940 homes. Builders stopped installing it once electrical loads increased beyond what it was designed to handle. It lacks grounding and struggles with modern appliances. Safety codes eventually made it obsolete.

Insurance companies often refuse coverage on homes with active knob-and-tube. Builders prefer modern wiring that supports higher amperage and safer grounding. Updating it is expensive, which is why buyers worry about it. No builder wants to knowingly install a system that fails current codes.

5. Aluminum Branch Circuit Wiring

Aluminum wiring was briefly popular in the 1960s and 1970s due to copper shortages. Builders moved away from it after discovering its tendency to loosen at connections. Loose connections increase fire risk through overheating. While aluminum is still used for service lines, it’s avoided inside walls.

The issue isn’t aluminum itself but how it expands and contracts. Builders don’t want callbacks for electrical failures years later. Copper proved more stable and forgiving. As a result, aluminum branch wiring became a cautionary tale rather than a standard practice.

6. Lead-Based Paint

Lead paint comes up constantly because people associate it with durability and rich color. Builders stopped using it after research showed how toxic lead dust is, especially for children’s brain development. The U.S. banned residential lead-based paint in 1978. Any legitimate builder today avoids it entirely.

Even small amounts of lead paint can contaminate a home during normal wear. Renovation work becomes more complex because sanding or scraping releases hazardous dust. Safer latex and acrylic paints now outperform old lead formulas in flexibility and longevity. There’s simply no performance upside anymore.

7. Single-Pane Windows

Buyers ask about single-pane windows because they’re cheaper upfront. Builders stopped using them once energy codes tightened and expectations changed. Single-pane glass leaks heat, causes condensation, and performs poorly in extreme temperatures. Double- and triple-pane units simply outperform them.

Energy efficiency is now a selling point, not a luxury. Builders also consider comfort and noise reduction, both weak points of single-pane windows. Modern glazing coatings and gas fills add real value. Installing single-pane windows today would be a competitive disadvantage.

8. Galvanized Steel Water Pipes

Galvanized pipes were once the standard for residential plumbing. Builders moved away from them because they corrode from the inside out. Over time, mineral buildup restricts water flow and degrades water quality. Failures tend to happen decades later, long after warranties expire.

From a builder’s perspective, long-term reliability matters. Copper and PEX don’t suffer the same internal corrosion issues. Galvanized pipes also complicate repairs and renovations. That’s why they’re now mostly seen in older homes, not new builds.

9. Cast Iron Drain Pipes (in Most Homes)

Cast iron drain pipes are still around, which is why buyers ask about them. Builders largely stopped using them in single-family homes due to cost and labor intensity. They’re heavy, difficult to cut, and slow to install. Plastic alternatives made construction faster and cheaper.

Cast iron also corrodes internally, leading to leaks and blockages. ABS and PVC resist corrosion and are easier to repair. Builders balance durability with efficiency, and plastics usually win that equation. Cast iron remains common only where sound control is critical, like some multifamily buildings.

10. Masonite Hardboard Siding

Masonite siding was popular because it was affordable and easy to paint. Builders stopped using it after widespread moisture failures became evident. The wood fibers swell, rot, and delaminate when exposed to water. Lawsuits in the 1990s effectively ended its widespread use.

Builders now favor fiber cement or engineered wood with better moisture resistance. Those materials handle rain and humidity far more reliably. Masonite taught the industry a hard lesson about exterior durability. Buyers still ask because so many older homes have it.

11. CCA-Treated Lumber (Chromated Copper Arsenate)

CCA-treated lumber was once standard for decks and outdoor structures. Builders stopped using it in residential settings due to arsenic exposure concerns. In 2003, it was phased out for most consumer uses. Handling and disposal posed health risks.

Modern pressure-treated lumber uses safer chemical formulations. Builders prefer materials that don’t raise safety questions for homeowners. The performance benefits remain without the toxicity concerns. CCA lumber is now mainly limited to industrial applications.

12. Asbestos Cement Siding

Asbestos cement siding is often remembered for its durability. Builders stopped using it because of the asbestos content, not performance issues. Cutting or breaking the siding releases hazardous fibers. Regulations made installation impractical and risky.

While the siding itself can last decades, removal is costly. Builders don’t want future owners facing abatement expenses. Fiber cement now offers similar durability without health concerns. Asbestos cement remains a legacy material, not a current option.

13. Oil-Based Interior Paints with High VOCs

Buyers ask about oil-based paints because they recall their toughness. Builders moved away from them due to high volatile organic compound emissions. VOCs contribute to indoor air pollution and health issues. Regulations and consumer demand pushed the shift.

Modern water-based paints now match or exceed oil-based performance. They dry faster, clean up easier, and smell less. Builders appreciate fewer complaints and faster project timelines. High-VOC oil paints simply don’t fit modern standards.

14. Early Barrier-Style EIFS (Exterior Insulation and Finish Systems)

EIFS gained popularity for its smooth stucco-like appearance. Builders stopped using early barrier-style systems after moisture intrusion problems surfaced. Trapped water led to rot and mold behind walls. Lawsuits and failures gave EIFS a bad reputation.

Modern EIFS systems are drainage-based and far improved. However, many builders remain cautious due to past issues. Traditional siding systems feel safer and more familiar. Buyers still ask because they remember the look, not the problems.

This post 14 Materials Buyers Ask About That Builders Stopped Using was first published on Greenhouse Black.