1. Vinyl Flooring

Vinyl flooring has come a long way, but contractors still say it tends to show wear earlier than homeowners expect. Heavy foot traffic can cause the top protective layer to dull, especially in kitchens and hallways. It’s also prone to scratches from grit or moving furniture, even when it’s a thicker plank. Many pros note that cheaper vinyl products, in particular, lose their luster within just a few years.

Moisture is another issue that shortens vinyl’s lifespan. If the subfloor isn’t perfectly level or stays damp, vinyl planks can curl at the edges. This creates gaps that attract dirt and make the floor look older long before it’s technically failing. Contractors say once curling starts, the material rarely goes back to looking “new.”

2. MDF Trim

Medium-density fiberboard trim is popular because it’s inexpensive and easy to paint, but it doesn’t age gracefully. Even minor moisture exposure can cause it to swell or crumble around edges. Contractors often see this around baseboards in bathrooms or kitchens where humidity lingers. Over time, the crisp lines that make trim look clean start to distort.

Once MDF absorbs water, it’s almost impossible to restore. The material becomes soft and spongy, making it lose its structural integrity. Paint can hide the early stages of damage, but it cannot prevent long-term deterioration. Pros frequently recommend solid wood in high-humidity areas for this reason.

3. Particleboard Cabinets

Particleboard cabinets work fine at first, but contractors say they rarely hold up over the long haul. The compressed wood fibers inside can sag or warp under the weight of stored items. Hinges also pull out more easily because the material doesn’t hold screws well. Over time, doors may stop closing properly or start drooping.

Moisture accelerates the decline dramatically. Even a small leak or repeated steam exposure can cause the panels to puff up. Once that happens, the cabinet’s surface delaminates and becomes impossible to repair cleanly. Contractors often note that homeowners usually replace particleboard cabinets years earlier than they planned.

4. Cheap Asphalt Shingles

Inexpensive asphalt shingles may look fine at installation, but they often age poorly regardless of brand. UV exposure causes them to dry out faster and lose protective granules. Without those granules, shingles become brittle and susceptible to cracking. Contractors regularly see premature wear on roofs installed with budget-grade materials.

Temperature swings make the problem worse. Shingles expand and contract daily, and lower-quality ones struggle to keep up. This leads to curling, which reduces the roof’s ability to shed water. Once curling starts, pros say the entire roof’s lifespan shortens dramatically.

5. Laminate Countertops

Laminate countertops scratch more easily than most people anticipate, especially in busy kitchens. The surface layer is thin, and once it’s scraped, the damage is permanent. Contractors frequently hear complaints about visible seams and edges fraying over time. Heat exposure from pots or appliances can also cause bubbling.

Moisture around sinks can get under the laminate and weaken the particleboard core. As the core swells, the top layer begins to lift, creating soft spots. This usually spreads faster than homeowners expect. Many pros say once swelling begins, replacement becomes the only practical option.

6. Hollow-Core Interior Doors

Hollow-core doors are affordable, but they simply don’t age well. Their lightweight construction means they dent and puncture easily. Contractors also see warping over time because the door lacks internal stability. In older homes, these doors often show wear far sooner than solid options.

Humidity makes them even more vulnerable. Seasonal moisture changes can cause edges to separate or bow. Repairs rarely look seamless because the material underneath is so thin. Many pros suggest upgrading when possible to avoid frequent replacement.

7. Faux Stone Veneer (Lower-Grade)

Contractors say budget faux stone veneer often deteriorates quickly outdoors. The color coating can fade significantly with sun exposure. Freeze–thaw cycles also cause pieces to crack or detach from the wall. Homeowners are sometimes shocked at how fast it loses its original charm.

Water infiltration is a major issue. If the installation isn’t perfect, moisture gets behind the veneer and weakens the adhesive. Over time, sections may loosen or fall off entirely. Pros consistently mention that proper waterproofing is essential, but cheap veneer still struggles in harsh climates.

8. Cedar Shingles (Untreated)

Cedar shingles look beautiful at first, but untreated versions weather quickly. Sun exposure causes uneven fading that many homeowners find unattractive. Contractors also see the wood dry out, making the shingles more brittle. Once cracking begins, the material deteriorates faster.

Moisture is just as damaging. Without regular treatment, cedar absorbs water and becomes susceptible to rot or mildew. This leads to soft areas and premature failure. Pros insist that constant maintenance is the only way to slow the aging process.

9. Plastic Outdoor Furniture

Contractors and landscapers often comment on how quickly plastic outdoor furniture degrades. UV rays cause it to fade and become chalky within a couple of seasons. The plastic also becomes brittle, making it crack easily. Lightweight designs make the problem even worse because they blow around and get damaged.

Heat fluctuations speed up aging. As plastic expands and contracts, stress points form. Eventually, joints loosen or fracture. Pros frequently recommend upgrading to metal or wood for long-term durability.

10. Stucco Without Proper Drainage

Stucco itself isn’t inherently bad, but improperly drained stucco ages terribly. Contractors often see moisture trapped behind the surface due to missing drainage mats or flashing. This causes bubbling, cracking, and dark moisture stains. Once water gets in, the damage spreads quickly.

Over time, trapped moisture leads to rot in underlying materials. The stucco then separates from the wall, creating structural concerns. Repairs require cutting out entire sections, not just small patches. Pros say the aging issues almost always trace back to installation errors.

11. Rubber Roof Membranes (Low-Quality EPDM)

Low-quality EPDM rubber roofing tends to degrade faster than promised. UV radiation dries it out, making it more prone to cracking. Seams can loosen over time, especially in climates with extreme temperature swings. Contractors often find that these roofs need patching well before their supposed lifespan.

Ponding water adds to the problem. If the roof isn’t sloped correctly, standing water accelerates membrane breakdown. This leads to leaks that spread without obvious warning signs. Pros strongly prefer thicker, higher-grade materials for longevity.

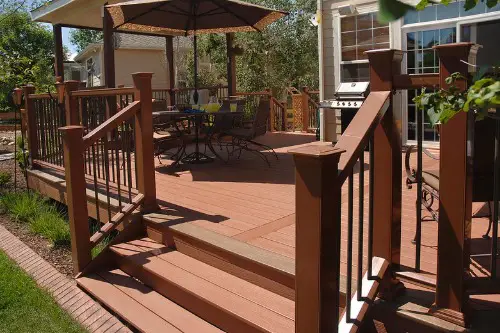

12. Composite Deck Boards (Early-Generation or Low-Quality)

Modern composite boards have improved, but contractors say older or cheaper versions still age poorly. Sun exposure can cause significant fading, especially in darker colors. Some boards also swell at the ends, creating a wavy look. Scratching remains an issue despite marketing claims.

Moisture trapped between boards can promote mold growth on early-generation composites. Unlike real wood, mold stains cannot simply be sanded out. This leaves boards looking worn long before they structurally fail. Pros often caution homeowners to research brands carefully before committing.

13. Low-Grade Fiber-Cement Siding

Contractors often point out that lower-grade fiber-cement siding doesn’t age as gracefully as premium versions. The boards may look sharp initially, but cheaper mixes tend to absorb more moisture over time. This leads to early paint failure as the surface begins to flake or develop hairline cracks. Homeowners are often surprised at how quickly the finish dulls despite being labeled “low maintenance.”

Moisture intrusion also causes the panels to swell at the edges. Once swelling begins, the siding can’t return to its original shape, leaving seams uneven and visibly aged. Repainting only hides the issue temporarily before the distortion reappears. Pros say installation quality helps, but low-grade cement boards simply break down faster than expected.

14. Budget Laminate Flooring

Budget laminate flooring frequently shows its age sooner than homeowners expect. Contractors note that the printed surface layer is thin and easily scuffed by daily foot traffic. Repeated friction from grit or pet claws quickly erodes the finish. Once scratches appear, they expose lighter material beneath, making the floor look patchy.

Moisture is equally unforgiving. Even small spills that sit too long can cause the planks to swell at the seams. As swelling spreads, the boards lift and distort, creating an uneven surface. Pros explain that unlike hardwood, laminate cannot be refinished, so early aging often means full replacement.

15. Aluminum Gutters (Thin Gauge)

Thin-gauge aluminum gutters tend to deform quickly, even when installed correctly. Contractors often see them dent from minor impacts like falling branches or ladders. These dents restrict water flow and create low spots where debris collects. Over time, the gutters lose their shape and look noticeably tired.

Temperature swings worsen the problem. Expansion and contraction loosen fasteners and cause seams to separate. Once gaps form, water spills behind the gutter instead of moving through it. Pros say upgrading to a thicker gauge is the only reliable way to avoid constant repairs.

16. Pressed-Wood Furniture

Pressed-wood furniture often appears stylish at first, but it’s notorious for aging poorly. Contractors and installers frequently see edges chipping or peeling after just a few years of light use. The thin veneer layer hides the weak core underneath, which cannot handle heavy loads. Over time, shelves bow and joints loosen, making the piece look worn-out.

Humidity makes deterioration even faster. As the core absorbs moisture, it expands unevenly and warps permanently. The veneer then bubbles or separates, leaving visible ripples across the surface. Pros warn that once this happens, repairs rarely look clean or last long.

17. Cheap PVC Deck Railings

Lower-cost PVC railings tend to show aging signs surprisingly quickly. Contractors report that sun exposure causes them to discolor unevenly, turning patches yellow or chalky. The surface also becomes brittle, making the rails crack under minor pressure. These cosmetic issues often appear long before structural failure.

Heat plays a major role in deformation. In hot climates, the material can soften enough to bow or twist. Once the shape changes, it can’t be restored to its original form. Pros say higher-quality vinyl holds up better, but bargain-grade PVC simply doesn’t withstand weathering.

18. Fiberglass Shower Inserts (Thin Molded Types)

Thin molded fiberglass shower inserts often lose their appearance faster than homeowners anticipate. Contractors point out that the gel coating scratches easily, leading to a dull and uneven finish. Cleaning with abrasive products accelerates the damage, widening scratches into visible cloudy patches. Over time, the surface loses its shine and feels rough.

Flexing is another long-term problem. Thin panels bend slightly under weight, causing fine stress cracks to form. These cracks trap dirt and discolor, making the shower look older than it is. Pros recommend thicker, reinforced units to avoid premature aging.

19. Vinyl Window Frames (Low-End)

Low-cost vinyl windows often degrade before their expected lifespan. Contractors notice early warping in frames exposed to intense sun, particularly on south-facing walls. As the vinyl softens and bends, the sash may no longer seal tightly. This leads to drafts and a noticeably aged appearance around the edges.

Temperature fluctuations also take a toll. Repeated expansion and contraction cause the joints to separate slightly, creating gaps that let moisture in. Over time, this moisture leads to staining, mold spots, and reduced insulation performance. Pros emphasize that while vinyl can be durable, cheaper versions nearly always show premature wear.

This post 19 Materials Contractors Say Age Poorly No Matter the Brand was first published on Greenhouse Black.